Technology

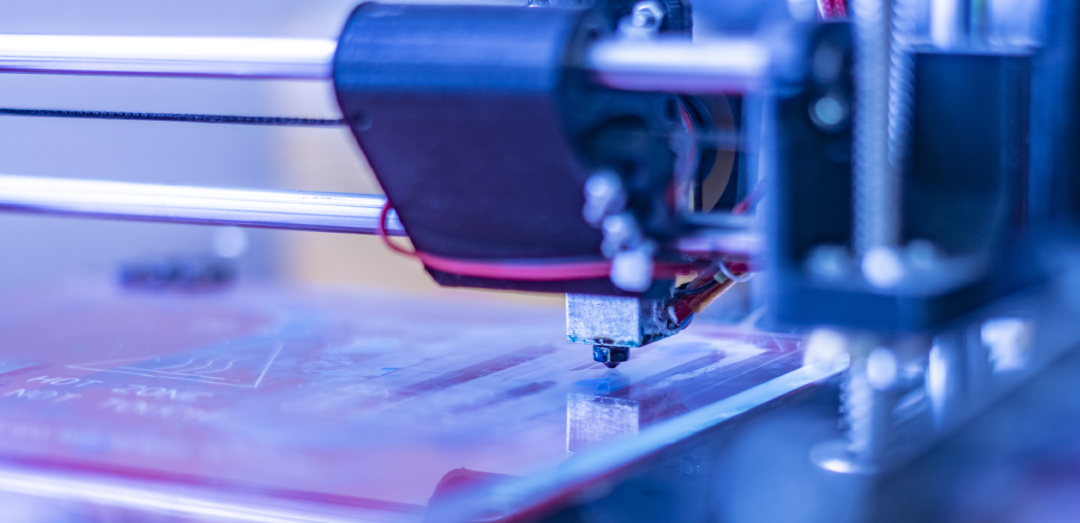

NRC-IRAP Metal Additive Program

Interested in trying one of your designs in 3D printing? Not sure on the feasibility or the cost? Limited spots available – program ends March 2020.

Overview

CME’s Canada Makes is administering a program to assist IRAP clients in determining the feasibility of using metal additive manufacturing processes for their own applications.

The advantages of metal additive manufacturing/3D printing are extreme design flexibility and ability to manufacture hollow shapes, ability to have multi-material multilayered structures, ability to make one-off parts without any additional tooling and much more. One of the most promising applications has been manufacturing of custom fixtures and tooling for various manufacturing processes.

Interested in undertaking a feasibility study of metal additive manufacturing for your application and R&D needs? A maximum of $5,000 CAD per project is available towards the cost of a CME Qualified Service Provider (QSP) to design and manufacture your additive metal prototype.

Are you a supplier to an OEM and have a collaborative project to help create a sustainable additive metal manufacturing supply chain for the Canadian manufacturing sector? A maximum of $10,000 CAD per project is available towards the cost of a CME Qualified Service Provider (QSP) to design and manufacture your additive metal prototype.

Metal Additive Demonstration Program

The Metal Additive Manufacturing (AM) Demonstration Program is managed by CME Canada Makes with funding from NRC-IRAP. The program is designed to help Canadian companies by de-risking initial trials, increase their awareness and understanding to the advantages of metal additive manufacturing (AM) technology. The program focuses on additive manufacturing technologies such as laser powder bed such as Direct Metal Laser Sintering (DMLS), Laser Direct Energy Deposition (LDED), electron beam (EB) and other emerging metal AM technologies.

Canada Makes works with a group of leading Canadian service providers of metal AM technologies who provide participating companies guidance and advice to the advantages as well as opportunities offered by adopting AM. A primary goal of the program for Canada’s industry to learn about the cost savings associated with AM, and how they can take advantage of the main areas where AM excels at; light-weighting of parts, parts consolidation and complexity of design, the sweet-spots for metal AM.

The program demonstrates the ability to produce low volume parts for diverse applications; including the repair of high performance/low cost tools, dies and plastic and composite moulds for stamping, forming, trimming high strength alloy steels and much more.

Canada Makes assists in assessing the needs of manufacturers and how best it suits their business model. Some have needs like the fabrication of obsolete legacy parts no longer available, AM offers a relatively inexpensive solution. Others are tooling companies looking to improve productivity and gaining a competitive edge by adopting conformal cooling. Be they SMEs or larger corporations, AM is changing how we build things and this program is there to help them learn about the disruptions coming to their sector but also de-risks their initial trials of this exciting technology.

The results will create awareness and encourage the adoption of AM technology, thus improving Canada’s manufacturing and exporting sectors and our global competitiveness, resulting in new technology skills and increased employment opportunities in Canada.

Through the delivery of this program Canada Makes, it became apparent that many of the same questions and concerns were shared by new comers to this technology. Therefore Canada Makes developed two interactive guides, the Metal Additive Process Guide & Metal Additive Design Guide designed to assist businesses new to metal AM wanting to learn about process and designing for metal AM (DfAM). The Guides are easy to use, interactive and offer useful information for the adoption of this technology.

Access is free although we request that you register. Thank you and enjoy!

For more information, please contact:

John Rodic, Program Manager

John.rodic@cme-mec.ca I (905)741-2515

Who Can Apply for Funding

Any small-to-medium sized manufacturer meeting the NRC-IRAP eligibility criteria of this program is encouraged to apply. Projects are assigned to CME’s Metal Additive Manufacturing Qualified Service Providers (QSP’s) who support the design process and build the part. Eligible and approved projects are paid up to the maximum eligible amount by NRC-IRAP through CME’s Canada Makes program.

PROJECT DEADLINE

All projects must be completed and Qualified Service Provider invoices received

by March 20th, 2020, to be eligible for reimbursement.

HAVE MORE QUESTIONS?

For more information, please contact:

John Rodic, Program Manager

John.rodic@cme-mec.ca I (905)741-2515

Find your local NRC_IRAP Representative

For information on NRC-IRAP or to speak with an Industrial Technology Advisor (ITA), please contact the NRC-IRAP regional office nearest to you or call the toll-free number: 1-877-994-4727